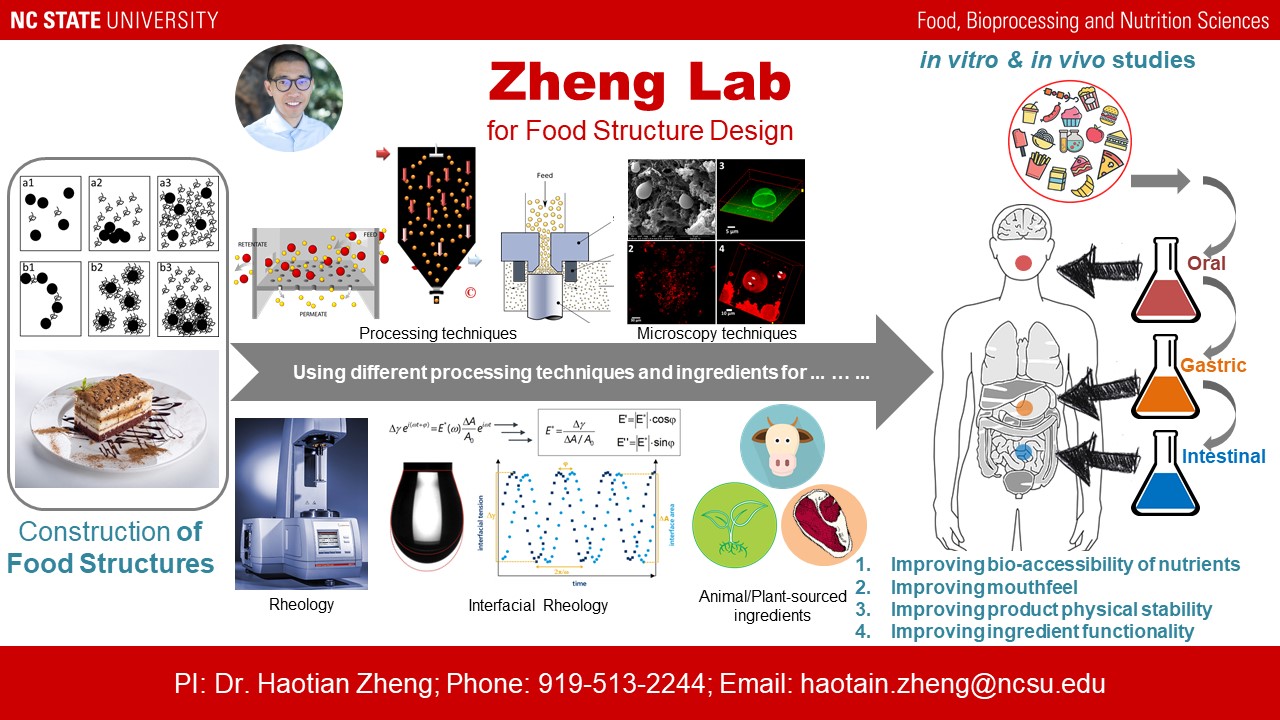

Research Topics

We are a group of food scientists working hard to make processed foods tastier, healthier and less impactful to the environment.

We do both fundamental and applied research for revealing mechanisms of formation of food structures. The obtained knowledge will be used in manipulating food structures for 1. improving processability of food materials; 2. for improving physical stability of processed food products; 3. for improving textural attributes (mouthfeel) of processed foods; 4. for improving digestibility and/or bioaccessibility of nutrients.

A specific optimum/functional food structure is a result of a combination of a series of processing treatments and a mixture of a number of food ingredients. In our group, we specifically focus on the part of food ingredient functionality. This part of work involves 1. further understanding of functionality of food ingredient in construction of a food structure; 2. manipulation of ingredient functionality for the benefits of structure design. Ingredient application, ingredient characterization and ingredient modification works are all involved in our group.